PT.SSE-Van Der Horst Indonesia

– PT. SSE-VAN DER HORST INDONESIA (SSE-VDHI)

ww.sse-vanderhorst.co.id

PT. SSE-Van Der Horst Indonesia (SSE-VDHI) A joint member of the Van Der Horst Group Inc. and Singapore Technology Marine Ltd, was established in 1991. Its engineering services plant is located in Tangerang with a total area of 900 m2.

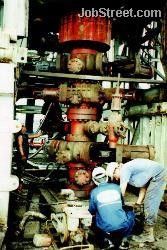

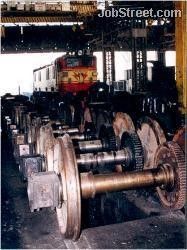

SSE-VDHI Workshop is one of the best equipped of its kind in Indonesia. Our capacities are:

Material Handling There are a total of 5 overhead cranes. Each of our two crane has at least one 5 ton crane and three crane has lifting capabilities of up to 10 tons and a forklift having lifting capabilities of up to 7 tons.

Shaft Turning Shaft turning up to 7 m in length with a diameter of 800 mm.

Vertical Turning Of the 5 vertical borers is the biggest borer with a 1.8 m turning diameter and a turning height of 1.7 m and with CNC capability.

Horizontal Boring Machines A total of 3 horizontal boring HBM machine. The largest is a German made Union. It has a long travel of 3 m, a vertical travel of 1.5 m and a table capable of supporting 10 tons.

Industrial Chrome Plating SSE-VDHI’s plating facility is the largest in Indonesia. The largest plating tank can accommodate work pieces of up to 5.5. m in length and 1 m in diameter for internal or external plating. Under special circumstances jobs up to 7.5 m length have been plated.

Roll Grinding A Waldrich roll grinder can accommodate rolls of up to 800 mm in diameter and 5 m length for grinding cylindrical and hollow rolls.

Crank Shaft Grinding Total length 8.5 m, maximum throw radius 350 mm and a total weight of 7.5 tons can be accommodated.

Honing Internal bores from 76 mm to 100 mm can be honed up to a length of 3 m.

Welding SSE-VDHI’s welding capabilities cover the entire spectrum of welding of pressure containing vessels as well as overlay welding with stainless steel or E.G. INCONEL.

Stress Relieving Furnace Items which require stress relieving can be treated in-house in our furnace. The internal dimensions of the furnace are 2.5 m by 2.5 m. Total load per charge can be 30 tons and the maximum temperature is 700Celsius.

Pressure Testing SSE-VDHI can pressure test up to 1500 PSI. Pressure test charts are provided for the record.

Supporting Services VDHES’ inspection department is fully trained in all kinds of inspection work including Magnaflux, Ultrasonic testing, Dye penetrant testing and all kinds of Metrology. In-house grit blasting facility ensures that no time is lost before inspection can commence.

– PT. BATTERY POWER SOLUTIONS INTERNATIONAL (BPSI)

ww.bpsi.co.id

Our Company

PT BPSI possesses an extensive global network in industry experience and expertise in the field of battery refurbishment.

We are well-positioned with affilates in 13 different countries. Utilising our state-of-the-art technology and equipment, alongside with our team of highly skilled and dedicated engineers, we will be able to identify our customer’s needs and provide them with the exact battery solution.

Our Business Model

Our business model focuses on a long-term partnership with our customers to develop a precise execution of managed services to provide substantial cost saving (operating expense) solutions for our customers by giving their old lead-acid traction batteries a second life. This is based on the re-use of old batteries, conducting an “open-heart” surgery, identifying the heart of the problem and re-engineering it to extend its usage back to nearly 100% of its brand new state.

The final process is the application of a proprietary additive that is environmentally friendly. Our professional and systematic battery refurbishment process is designed to significantly reduce the costs of battery maintenance for large vehicle fleets, telecommunication operates and individual battery consumers. This entire process is supported by an environmentally-friendly approachwhich is endorsed by BKPM.

Jika terdapat kesalahan pada profile perusahaan ini silahkan laporkan ke [email protected]

| Industri | Pelayanan Perbaikan & Pemeliharaan |

| Ukuran Perusahaan: | 51 - 200 pekerja |

| Tunjangan dan Lain-lain: | Waktu regular, Senin - Jumat, Bisnis (contoh: Kemeja) |

| Lokasi: | Jatiuwung |

Daftar Loker dari PT.SSE-Van Der Horst Indonesia

Foto Perusahaan